What is a DC generator?

The machine is an important thing that reduces human effort. A D.C. generator is an electrical rotating machine whose primary function is to convert mechanical energy into electricity. When the conductor cut magnetic flux, an emf is induced by Faraday’s law of electromagnetic induction process. D.C. generator working principle is almost similar to the D.C. motor.

What is the construction details of the DC generator?

Basically, there are two types of generators AC and DC. Now we will discuss the construction details of the DC generator. DC generator is an important machines for all places (industry, home, office, and others). It is used in several places to ensure to continuity of electricity supply. We know well that the construction and working principle of DC generator is not complex and it is similar to the DC motor. Now we are going to discuss the construction of a dc machine. The DC generator and D.C. motor have the same general construction. All DC machine has five principal components such as

- Field System

- Armature Core

- Armature winding

- Commutator

- Brushes

The other essential parts of a D.C. Generator are the magnetic frame, yoke, pole shoe, pole shoes, field or exciting coils, armature core and windings, brushes, end housings, bearings, etc.

Field system

The field system’s primary function is to produce a uniform magnetic field within which the armature rotates. It consists of several salient poles bolted to the inside of the circular frame. The yoke of the generator is usually made of solid cast Steel, whereas the pole pieces of the D.C. machine are composed of stacked lamination.

Armature core

The armature core is key to the machine shaft and rotates between the field poles. The armature core consists of slotted soft iron lamination about 0.4 to 0.6 mm thick to reduce eddy current loss that is stacked to form a cylindrical Core. The purpose of lamination in the Corps is to reduce the eddy current loss.

Armature winding

There are many definitions of armature winding in simple the voltage is induced in the winding and power transfer between mechanical and electrical systems. The armature is an indispensable and main component of the DC machine. Basically, EMF is generated by the relative motion of the magnetic field and armature.

Whenever the motor is started to rotate the generated Electromotive Force (EMF) opposes the armature current and then the armature winding in the DC machine converts electrical energy into mechanical energy and transfers this power to the machine shaft. The slot of the armature core holds insulated conductors that are correctly connected. It is known as armature winding. In the armature winding in which working EMF is induced the armature conductor is connected in series and parallel. The conductor is connected in series to increase the parallel path’s voltage level to improve the current status.

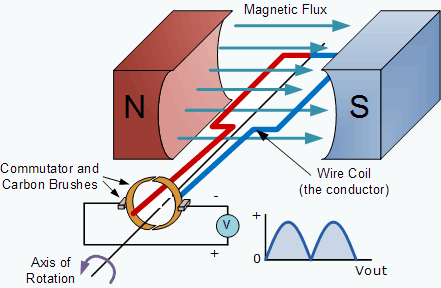

Commutator

The commutator is a mechanical rectifier that converts the alternating voltage generated in the generator winding’s armature into a direct voltage across the brushes. The commutator is made of copper segments insulated from each other slot by a mica sheet and mounted on the shaft of the D.C. machine. The commutator has two types of armature winding

- Simple lap winding

- Simple web winding

Brushes

The brush is an essential component of a D.C. generator or D.C. Machine. The purpose of brass is to make sure the electrical connection between the rotating commentator and stationary external load circuit the brass is made up of carbon and rests on the commutator the brass pressure is dusted utilizing an adjustable spring.

What is the working principle of a DC generator?

In a D.C. generator, field coils generate an electromagnetic field, and the armature conductors are rotated into the magnetic field. Thus, an electromagnetically produces emf in the armature conductors. Fleming’s right-hand rule provides the direction of the induced current. D.C. generators work on the principle of Faraday’s law of electromagnetic induction an armature coil is rotated rapidly between the field poles of the generator. The conductor coil, along with its magnetic core, is known as an armature.

What are the types of armature winding in DC machines?

Armature winding means that the voltage is induced in the winding and power transfer between mechanical and electrical systems. Armature resistance depends on the construction of the D.C. machine without for small machine. Its value is less than 1 ohm. There are two types of armature winding in DC machines, such as lap winding and wave winding.

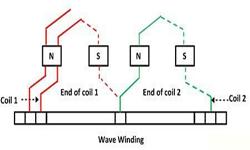

What is the simplex wave winding in a DC machine?

In simplex web winding in this arrangement, the armature coils are connected in series through the commodity segment so that the armature winding is divided into two parallel paths irrespective of the number of poles of the machine. If we compare between lap and wave winding then we will see that wave wound armature is used due to its higher efficiency.

What is the simplex lap winding in the DC machine?

Simplex lap winding is the arrangement where the armature coil connects in a series of right commutator segments. Lap winding in a DC generator is a type of winding that has two layers. Every coil of the layers is connected in series with one nearby it. In DC generator lap winding is used for low-voltage and high-current machines. The armature winding is divided into as many parallel paths as several DC generators or machine poles.

What are the main parts of a DC generator?

A DC Generator is an electrical device that converts mechanical energy into electrical energy. It mainly consists of three main parts, the magnetic field system, armature, commutator, and brush gear. The other essential components of a DC Generator are a magnetic field and yoke, pole shoes, field coil, exciting coils, armature core and windings, brushes, end housings, bearings, etc. The diagram of the essential parts of a four-pole DC Generator or DC Machine is shown below

- Pole Core and Pole Shoes

- Field coil or Exciting Coils

- The armature of the DC Generator

- Bearings

- Shaft

Pole core and pole shoe

The Pole Core and Pole Shoes are fixed to the magnetic frame or yoke by bolts. Since the poles, project inwards they are called salient poles. Each pole core has a curved surface. Usually, the pole core and shoes are made of thin cast steel or wrought iron laminations riveted together under hydraulic pressure. The poles are laminated to reduce the Eddy Current loss. The pole core serves the following purposes given below.

- It supports the field or exciting coils.

- They spread out the magnetic flux over the armature periphery more uniformly.

- It increases the cross-sectional area of the magnetic circuit, as a result, the reluctance of the magnetic path is reduced.

Field coil or Exciting Coils

Each magnetic pole core has one or more field coils (windings) placed over it to produce a magnetic field. Pure copper wire is used for the construction of field coils. The field coils are wound on the former and then placed around the magnetic pole core. When a direct current (D.C.) passes through the generator’s field winding, it magnetizes the poles, which produces the flux. The field coils of all the field poles are connected in series so that when current flows through them, the adjacent magnetic poles attain opposite polarity.

Armature of the DC Generator

All the DC machines have a coil of wire that is mounted in slots on cylindrical ferromagnetic material that is called an armature. The armature is free to rotate and mounted on the bearing and the armature is also mounted on the magnetic field and produced by the permanent magnet through the field coil. DC generator armature is the rotating part that is called the armature. The armature consists of an iron shaft upon which a laminated cylinder called Armature Core is placed.

Bearings

The ball bearings are fitted in the end housings part. The function of the paths is to reduce friction between the rotating and stationary parts of the machine. Mostly high carbon steel is used for the construction of bearings as it is a rigid material.

Shaft

The shaft is made of mild steel with maximum breaking strength. The post is used to transfer mechanical power from or to the machine, like the armature core, commutator, cooling fans, etc. The rotating parts are keyed to the shaft.

What are the Types of D.C. Generators?

The magnetic field in a D.C. generator is typically produced by Electromagnet rather than permanent magnets generators are generally classified according to their method of area excitation on this basis, the D.C. generator is divided into two classes:

- Separately excited D.C. generator.

- Self-excited DC generator

Separately excited D.C. generator.

D.C. generator field magnet winding is supplied from an independent external load called a separately excited generator. The output voltage of the separately excited generator depends on the speed of the rotation of the armature.

The greater the field current, the greater the rate, and the field current greater generate EMF separately excited D.C. generator is rarely used in practice. The DC generator is a generally Self-excited DC generator.

Self-excited DC generator

D.C. generator holes-filled magnet winding is supplied current from the output of the generator itself. It is called a self-excited generator. There are three main types of self-excited generators, depending on which field winding is connected to the armature.

- Series wound

- Shunt-wound

- Compound wound

Series wound generator

Series wound generator the field winding is connected in series with the armature winding so that the whole armature current flows through the field winding and load. The series generator has very high starting torque, and it is rarely used except the particular purposes.

Shunt Wound

In the Shunt-wound generator, the shunt generator’s field is connected in parallel with the armature winding so that the terminal voltage of the generator is applied across it. The shunt winding has many turns and high resistance; therefore, only a part of the armature current flows through the shunt field winding, and the rest flows through the load.

Compound Wound Generator

The compound wound generator has two sets of field winding connected in the compound generator on each pole. One field winding is connected in series, and another is connected in parallel with the armature. There are two types of compound wound generators.

- Short shunt, in which only shunt field winding is connected in parallel with the armature

- Long shunt, in which shunt field winding is connected in parallel with both series field and armature winding.

What are the Losses of the DC Machine?

We know that the efficiency of a machine is reduced due to the losses. If we would like to increase machine efficiency we must reduce the loss. If we talk about the DC generator then we will see that the DC machine efficiency is not very high due to its more losses. To increase the commercial efficiency of DC generators we must reduce the losses. All these losses appear as heat and raise the temperature of the machine. Machine efficiency decrease due to the various types of losses. The losses in DC generators may be divided into three main classes, such as

- Copper loss

- Iron or core loss

- Mechanical loss

Copper Losses

The losses occur due to currents in the various winding of the machine. There are three types of copper losses.

- Armature copper loss

- Shunt field copper loss

- Series field copper loss

Iron or Core loss

Iron or core losses occur in a D.C. machine’s armature due to armature rotation in the poles’ magnetic field. There are two types of Iron or core loss.

- Hysteresis loss. It occurs in the armature of the D.C. machine.

- Eddy current loss. It occurs when the armature rotates in the poles’ magnetic field and e.m.f. is induced in which circulates eddy current in the armature core.

Eddy current depends on the square of lamination thickness. For this reason, it should be kept lamination thickness s as small as possible. Iron loss and mechanical losses together are called stray losses.

Mechanical loss

Mechanical loss occurs due to friction loss (i.e., bearing friction, brush friction) and windage loss (i.e., air friction of rotating armature).

- Constant loss

- Variable loss

Constant loss

Constant loss in a D.C. generator means that the load remains constant at all loads is known as the constant loss. There are three types of constant losses in a D.C. generator

- Iron loss

- Mechanical loss

- Shunt field loss

Variable loss

The losses in D.C. Generator vary with load and are called variable losses. A variable loss is increased and decreased with the load. It means if the load on the machine increase then the loss is also increased. There are two main types of variable losses in a D.C. generator, such as

- Copper loss in the armature winding

- Copper loss in the series field winding

Total loss = Constant losses + variable losses